Technologies

We’re designing the first neural implant that will let you control a computer or mobile device anywhere you go.

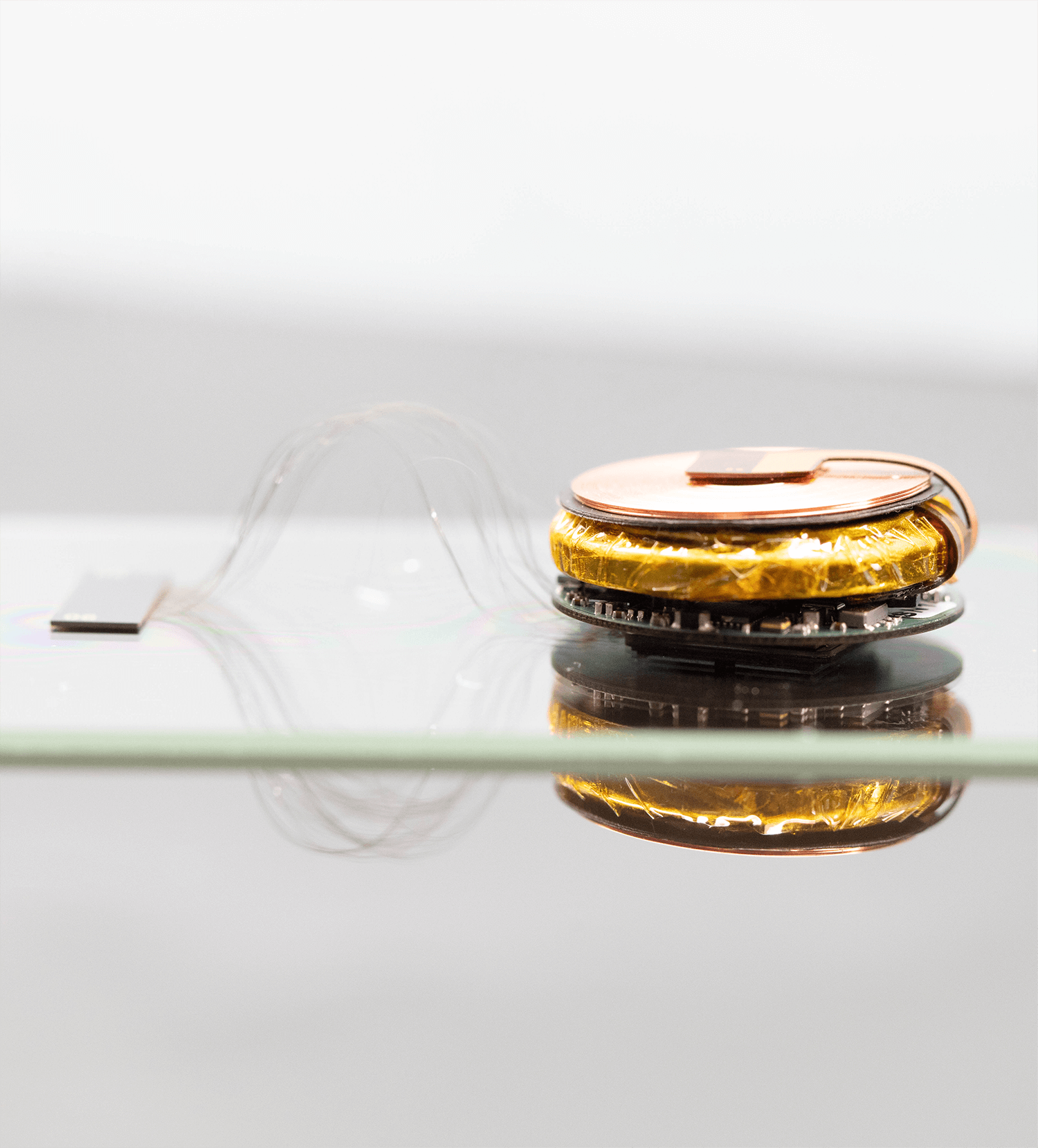

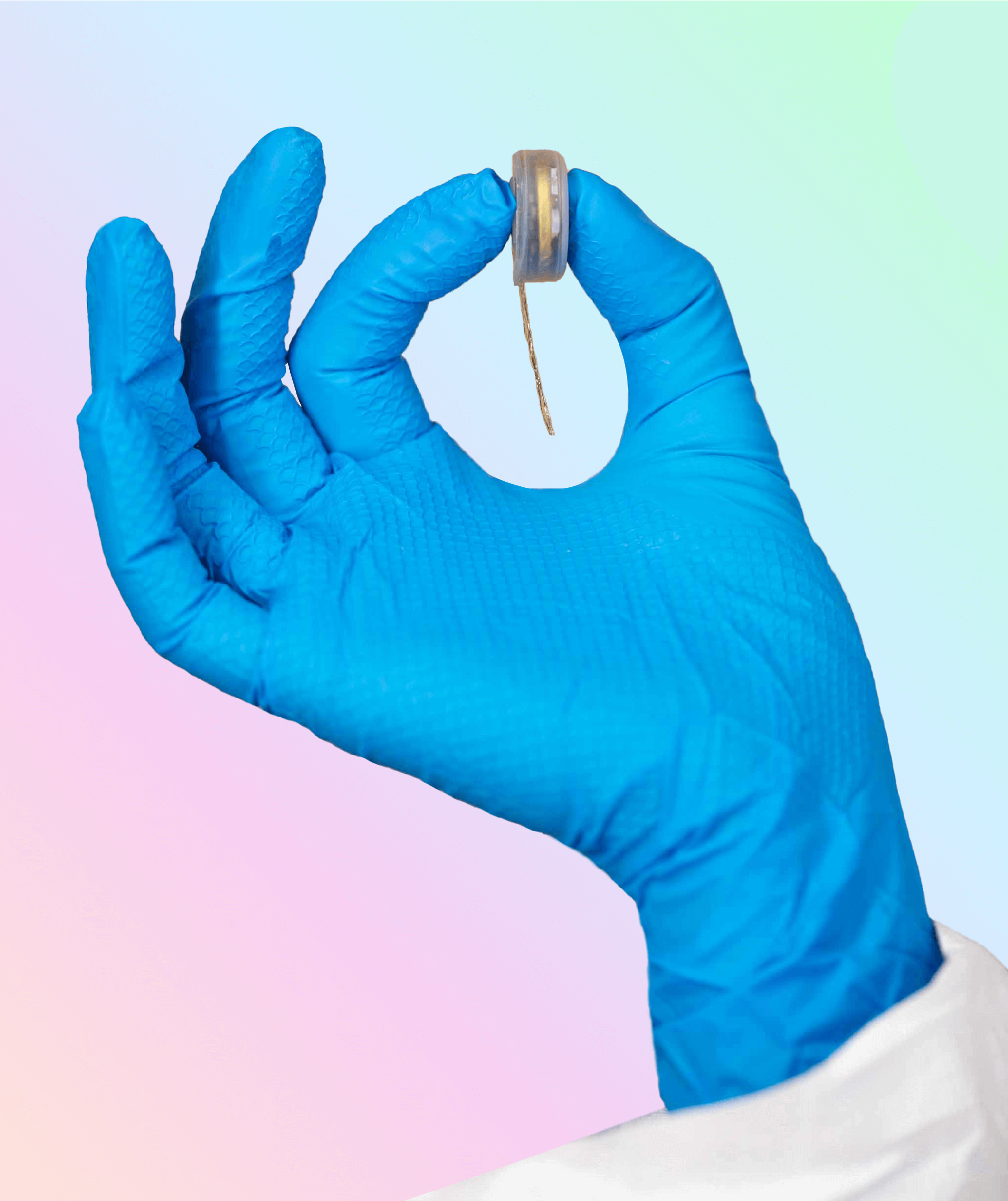

Micron-scale threads are inserted into areas of the brain that control movement. Each thread contains many electrodes and connects them to an implant, the Link.

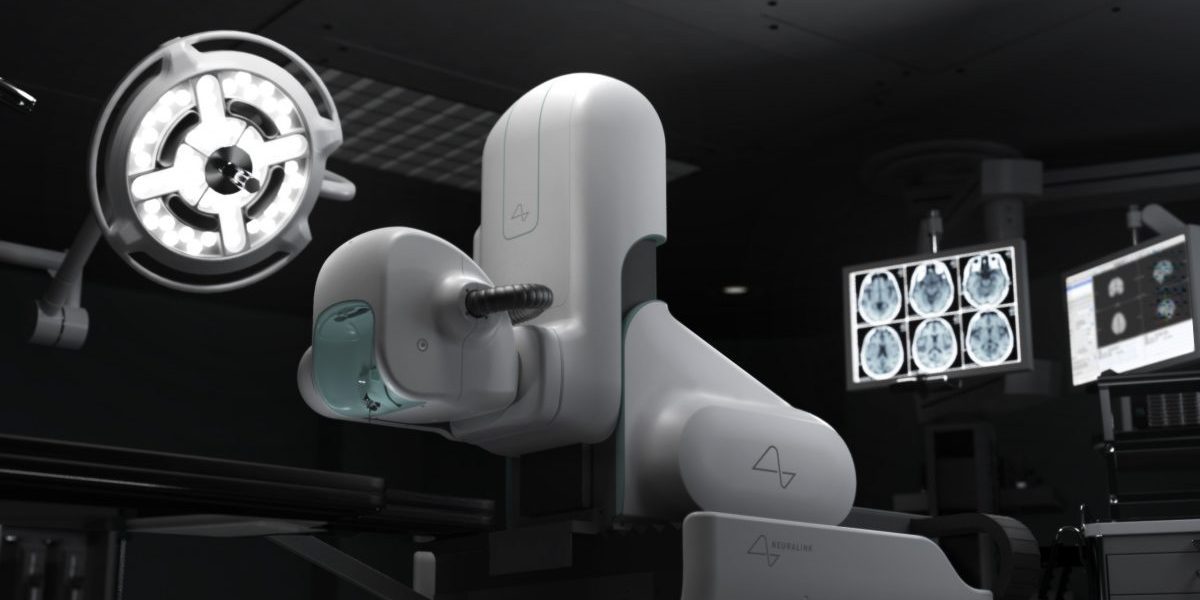

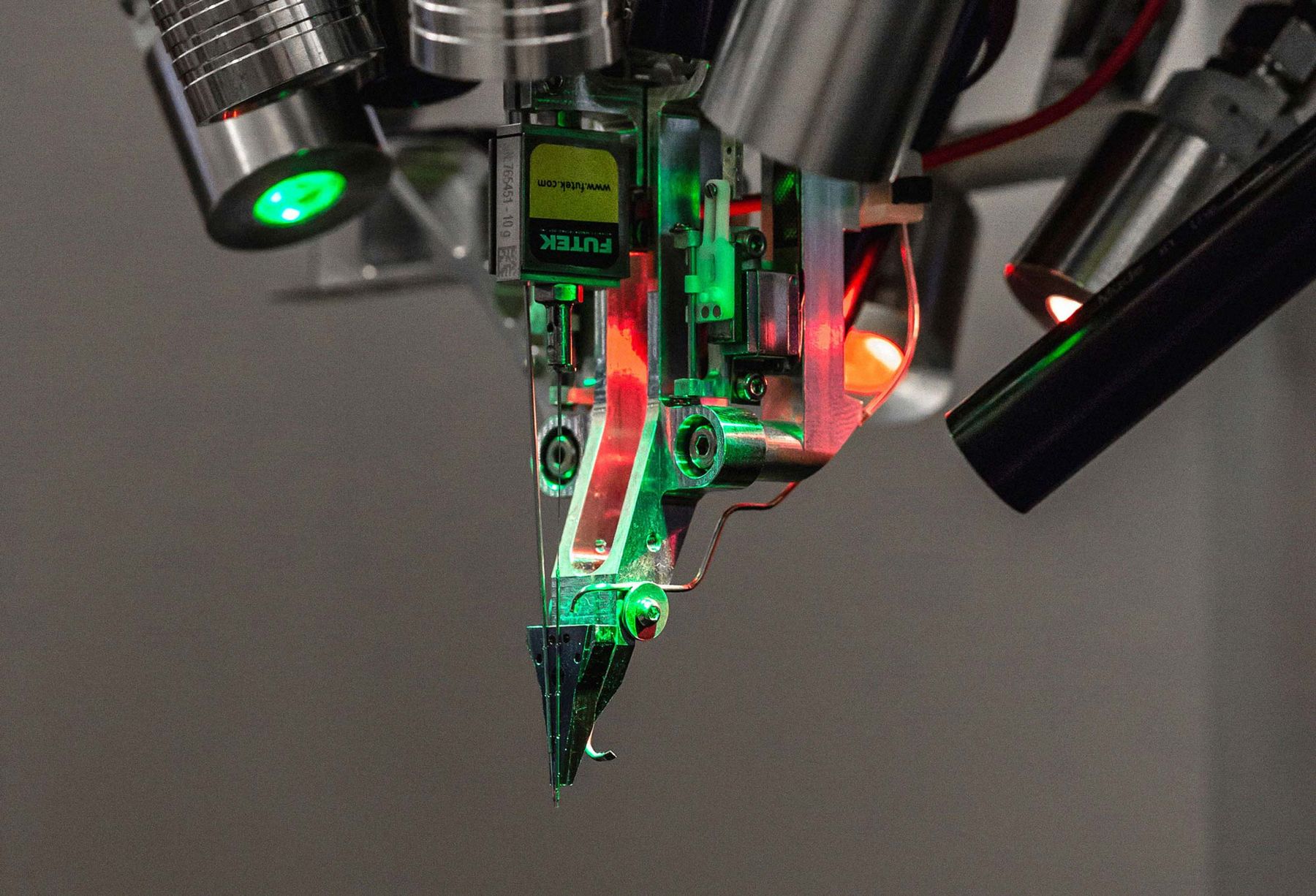

Neuralink collaborated with Woke Studios, a creative design consultancy based in San Francisco, to design the plastic casing (but not the technical components) of the robot sewing machine. The machine employs optical coherence tomography for real-time brain tracking and five axes of motion to access implant sites around a patient’s head, as well as a 150-micron gripper for grasping and releasing threads using a 40-micron needle.

The surgery consists of three parts: opening, inserting, and closing. A neurosurgeon takes care of opening, which involves creating an incision in the skin and removing a small piece of skull and any nearby dura membrane. Then the robot uses its cameras and sensors to insert the wires (or threads, as Neuralink calls them) into the brain while avoiding vasculature up to a depth of up to six millimeters. Finally, the surgeon secures the implant such that it replaces the piece of removed skull and closes.

The wires — which measure a quarter of the diameter of a human hair (4 to 6 μm) — link to a series of electrodes at different locations and depths. At maximum capacity, the machine can insert six threads containing 192 electrodes per minute.

A single-use bag attaches with magnets around the machine’s head to maintain sterility and allow for cleaning, and a table attached to a mechanical fixture ensures a patient’s skull remains in place during insertion. The machine’s “body” attaches to a base, which provides weighted support for the entire structure, concealing the other technologies that enable the system to operate.

News